| Min. Order: | 20000 Meter |

|---|---|

| Trade Term: | FOB,CIF,EXW |

| Payment Terms: | L/C, T/T |

| Place of Origin: | Jiangsu, China (Mainland) |

| Means of Transport: | Ocean |

| Production Capacity: | 5,000,000 Meters/Month |

| Packing: | Customized |

| Delivery Date: | 20 Days | Brand Name: | Kronos |

|---|---|---|---|

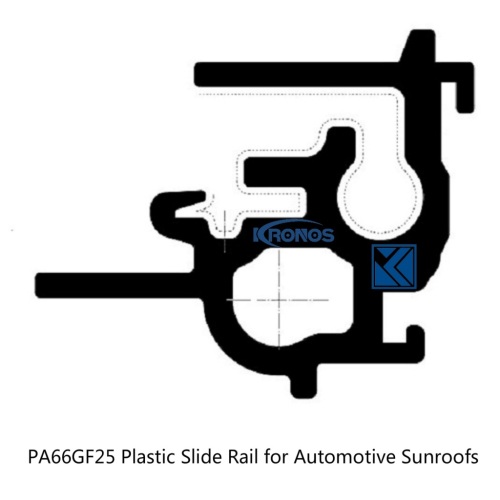

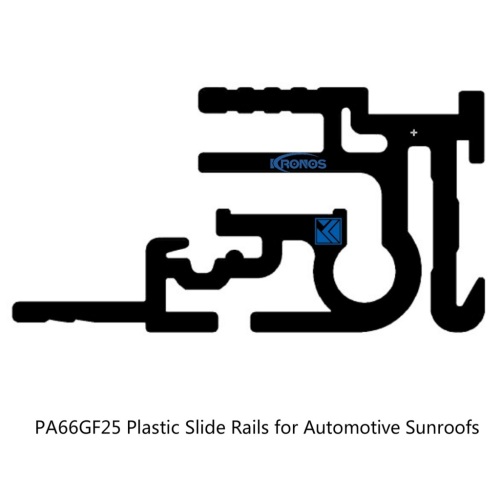

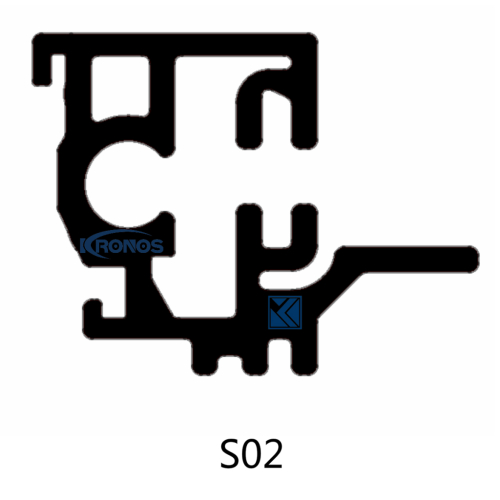

| Product Name: | Polyamide Slide Rails for Automotive Sunroofs | Material: | PA66 GF25 |

| Color: | Black | Width: | As per auto-makers' designs |

| Density: | 1.30±0.05 g/cm3 | Standard Length: | 6 Meters/Piece |

| Certificate: | IATF 16949:2016 | Processing: | High Precision Polyamide Extrusion |

| Standard Carried: | European Standard EN 14024:2004 & GB/T 23615.1-2017 | Application: | Automotive Sunroofs Mechanism |

Overview

The lighter of a vehicle, the further it can travel. The trend is to make vehicles lighter for maximum efficiency. Taking the automobile sunroofs slide rails/blind rails for example. Within the auto sunroof mechanism, slide rails are used to guide the glass panel and open/close the car sunroof. It requires a robust, high-precision solution for the smooth operation of the roof throughout the lifetime of the vehicle. Most of today's auto sunroofs slide rails are made of aluminum which is heavy in weight. Using lightweight, plastic profiles instead of heavier metal components can help vehicle manufacturers to gain a competitive edge in many ways.

Automotive sunroof manufacturuers like Webasto, Inteva, Inalfa have already used light-weight high-precision plastic profiles to replace the heavy aluminum components for some models. These plastic materials must be corrosion-resistant, match their surround materials and reduce maintenance needs. These are where Kronos's glass fiber reinforced Polyamide Vehicle Profiles come into play.

Kronos Precision Extrusion is an innovative Singapore-Germany joint venture which leads the way in developing and manufacturing Thermal Insulating Polyamide Profiles with Astonishing High Precision Thermoplastic Extrusion process and techniques. We offer a range of standard and custom-made extruded profiles from Virgin Polyamide 66/Polyamide 6 (PA66/PA6 or Nylon 66/Nylon 6) and other materials for constructional, commercial, institutional, automotive, and engineering applications.

Made from high-performance hard-wearing Polyamide 66 (PA66 or Nylon 66) with Fiberglass Reinforcement, Kronos's plastic vehicle slide rails offer an extremely reliable alternative that can meet the toughest performance demands in terms of stability and resistance to keep your vehicles running efficiently for longer. Our plastic mixtures can effectively reduce odour formation, noise levels, and are expandable and flexible — adapted to the behaviour of surrounding components. Fully customizable, our high-precision plastic vehicle profiles can be made to your individual requirements and in the finish you desire.

Kronos Precision Extrusion thrives upon Wide and Intricate polyamide extrusions that challenge today's extrusion capabilities. If you buy Polyamide Profiles from Kronos Precision Extrusion, you'll immediately know just how accurate they are and how precisely they fit together with your product.

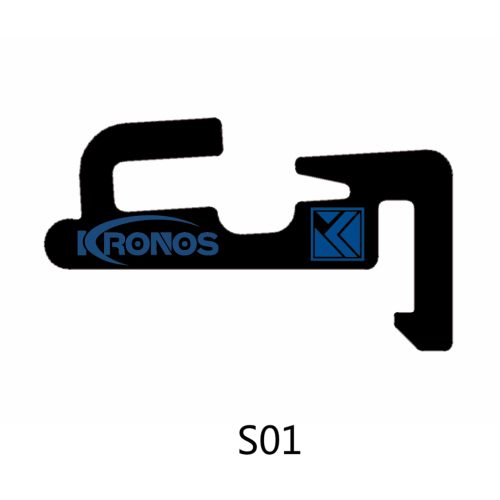

Product Name: Lightweight Fiberglass Reinforced Polyamide Slide Rails/Blind Rails for Automotive Sunroofs

Manufacturer: Kronos Precision Extrusion

Kronos Extrusion Model No.: S01

Main Material: Virgin Polyamide PA66 or PA6 + Pure Glass Fiber

Processing: High Precision polyamide extrusion

Standard Length: 6 meters/piece or customized

Profile Density: 1.30 ± 0.05 g/cm³

Shore Hardness: 80

Polyamide Slide Rail Color: Black

Standards: European Standard EN 14024:2004 & Chinese GB/T 23615.1-2017

Kronos Extrusion Certification: IATF 16949:2016

Benefits of Polyamide Slide Rails/Blind Rails/Guide Rails for Automotive Sunroofs:

Lightweight - it's about 50% lighter than traditional aluminum slide rails

Silent - Offer quiet movement and operation

Smooth - Offer Lubricant-Free movement

Long-Lasting, High Precision with Excellent Reliability & Stability

Hard-Wearing - Virgin Polyamide 66 with 25% Fiberglass Reinforcement guarantees the strength

Thermally Resistant

Maintenance-Free

Fully-Customizable - Ease of Integration and Installation for the Auto Sunroofs manufacturers

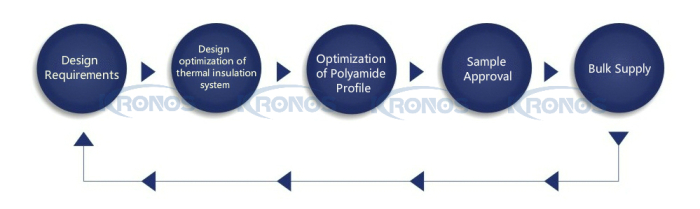

World-Class technical know-how and extensive experience in high precision thermoplastics extrusion & fabrications allows us to work closely with your design team to meet your most critical needs. The Kronos engineering team delivers prototypes quickly once your design is finalized. Kronos Precision Extrusion understands the importance of hitting critical timelines for new product development projects. Therefore, we offer a quick turnaround to help speed up your process development to ensure you hit your project milestones on time.

Our best-in-class specialists possess extensive expertise and technical know-how in new product development of thermoplastic extrusions, which ensures us to be flexible and quickly adaptable to meet your specific needs. Kronos can do extrusions others say Can't Be Done. Our manufacturing capabilities span a broad range of products and thermoplastic polymers which makes us the perfect partner for all of your standard and tailor-made high precision thermoplastic profiles extrusion needs.

Kronos Precision Extrusion is listening to it's customers' requirements and understands their specific concerns and needs. We are able to provide "ALL" professional services during the entire process of the Product Development Cycle with customer suitable "Turn Key" Solutions.

Kronos Precision Extrusion drives the automotive industry forward with efficiency. Our High Precision lightweight plastic vehicle profiles help to make automobiles more efficient and are an essential factor when it comes to constructing the cars of the future.