| Min. Order: | 20000 Meter |

|---|---|

| Trade Term: | FOB,CIF,EXW |

| Payment Terms: | L/C, T/T |

| Place of Origin: | Jiangsu, China (Mainland) |

| Means of Transport: | Ocean |

| Production Capacity: | 2,000,000 Meters/Month |

| Packing: | Fumigation-Free... |

| Delivery Date: | 15 Days | Brand Name: | Kronos |

|---|---|---|---|

| Product Name: | Polyamide Insulating Profiles | Material: | PA66 GF25 |

| Color: | Black | Width: | 30mm |

| Density: | 1.30±0.05 g/cm3 | Standard Length: | 6 Meters/Piece |

| Packaging: | Lineal | Processing: | High Precision Polyamide Extrusion |

| Standard Carried: | European Standard EN 14024:2004 & GB/T 23615.1-2017 | Application: | Aluminum Profiles, Thermal Break Aluminum Windows and Doors |

Overview

What is Polyamide (PA)?

Polyamide (PA), commonly referred to as Nylon is a synthetic thermoplastic (a plastic material that becomes pliable or moldable above a specific temperature and solidifies upon cooling) linear polymer (a large molecule whose components are bound by a particular type of bond.). Nylon is a good choice for a variety of applications, such as extruded parts for Automotive, Aerospace and Food Service to Commercial and Industrial use. Since polyamide has very similar thermal expansion coefficients to aluminum, which makes it the ideal Thermal Barrier for Thermally Broken Aluminum Systems. Polyamide Insulating Profiles reduce internal aluminum frame stress effectively and will not separate over years of seasonal hot-cold cycles. Water and air will not penetrate this superior Thermal Break.

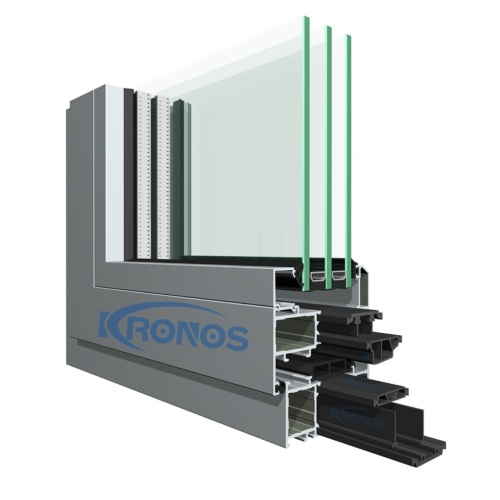

What is Thermal Break?

A Thermal Break, Thermal Strut, or Thermal Barrier is an element of low thermal conductivity placed in an assembly to reduce or prevent the flow of thermal energy between conductive materials. The thermal broken system consists of two independent aluminum profiles with similar or unlike shapes connected by extruded Polyamide Strips(Polyamide Profiles) in order to obtain one monolithic profile having low UV factor and low transmission sound. This will minimize heat transfer between the interior and exterior of aluminium doors and windows, which will improve the energy saving much better than traditional systems.

Polyamide Insulating Struts reduce internal aluminum frame stress effectively and will not separate over years of seasonal hot-cold cycles. Water and air will not penetrate this superior thermal barrier.

Who is Kronos Precision Extrusion?

Kronos Precision Extrusion is an innovative Singapore-Germany joint venture that leads the way in developing and producing reinforced polyamide profiles. The state-of-the-art insulation technique used by Kronos, connects the outer chamber and the inner chamber through Fiberglass Reinforced Thermal Break Polyamide Strips. These strips provide a thermal barrier and come in various widths/depths and shapes.

Our polyamide profiles yield best-in-class thermal performance and exceeds not only current codes, but also exceeds every countries' stringent green building codes and standards in the market today.

Impeccable Quality, Extremely Smooth Surfaces, Tighest Tolerance, Outstanding High Precision, all of these set Kronos apart from other thermoplastics extruders in the world. If you buy Thermal Break Polyamide Profiles from Kronos Precision Extrusion, you'll know just how accurate they are and how precisely they fit together with the aluminum frames.

Wide and Complex polyamide extrusions that challenge today's extrusion capabilities are the jobs that Kronos thrives upon. We pride ourselves on taking polyamide extrusions challenges which others say too difficult.

Our friendly and professional team is committed to ensuring you're happy not only with the polyamide profiles and solutions you choose from us, but also the service you receive from everyone at Kronos Precision Extrusion. We listen to what our customers request of us, addressing these needs, always aiming to surpass your expectations.

Product Name: Thermal Insulation Polyamide Profiles, Thermal Break Polyamide Strips, Thermal Barrier Polyamide Profiles, Thermal Struts, Polyamide Struts

Manufacturer: Kronos Precision Extrusion

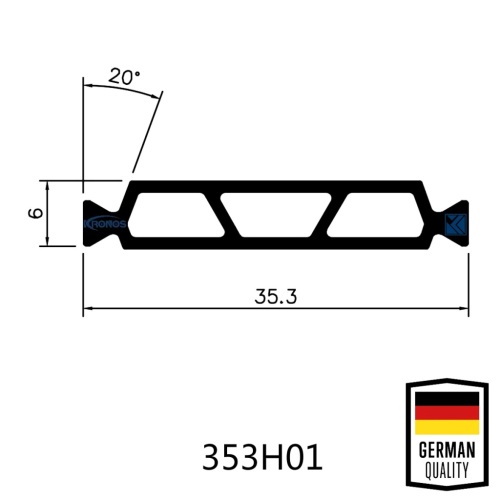

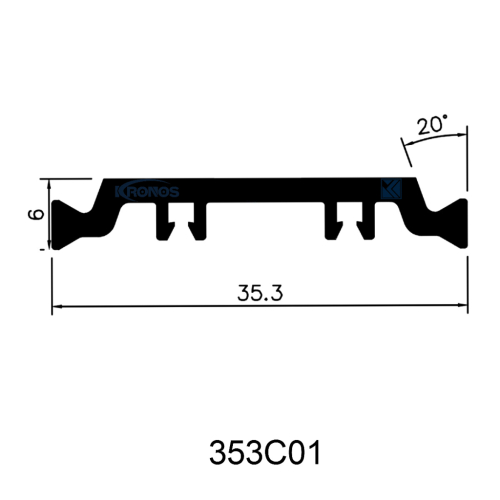

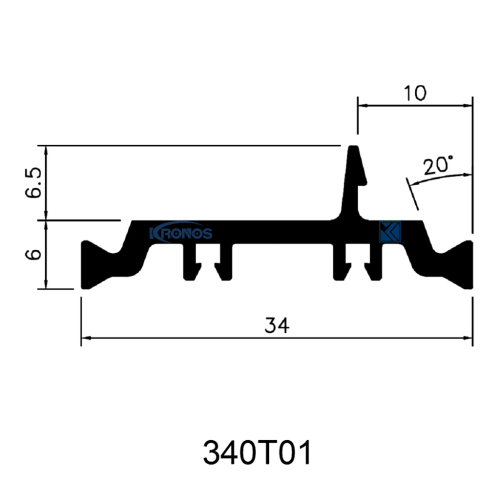

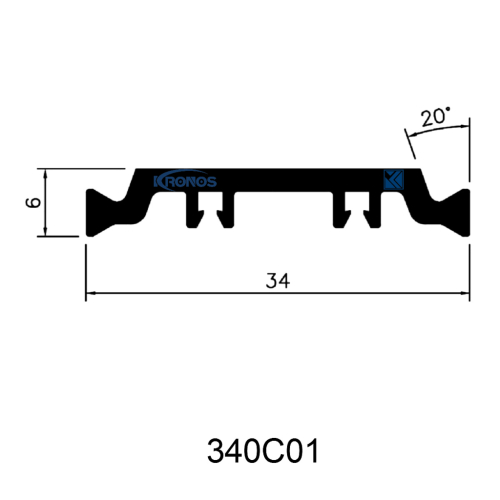

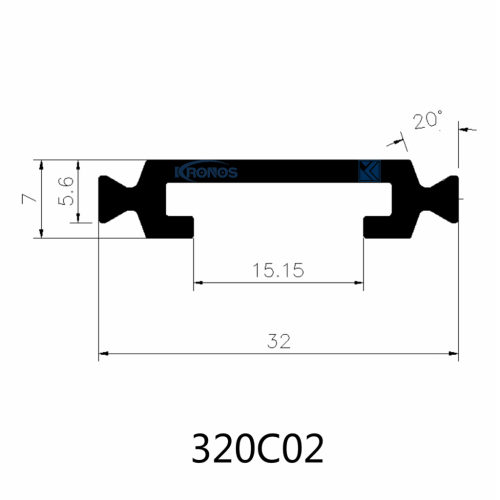

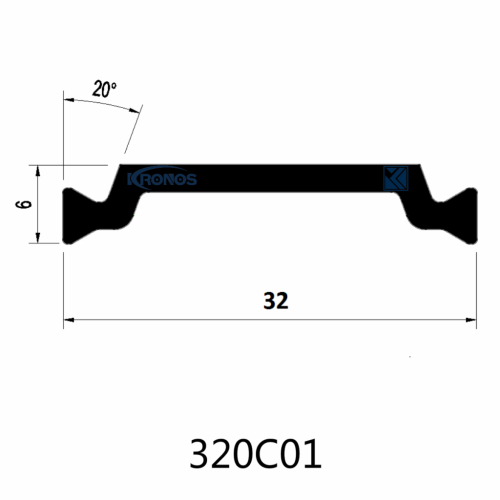

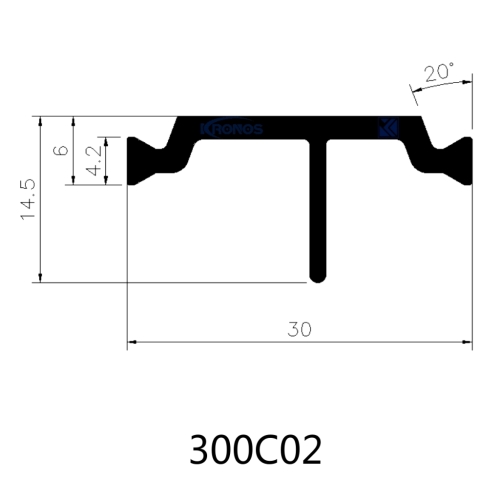

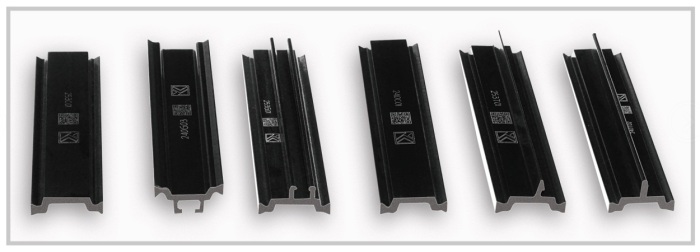

Kronos Extrusion Model No.: 300C02

Main Material: Virgin Polyamide PA66 + 25% Pure Glass Fiber

Processing: High Precision Polyamide Extrusion

Width: 30mm

Design: Euro Groove

Standard Length: Maximum 6 meters/piece or as per customers' requirements

Profile Density: 1.30 ± 0.05 g/cm³

Shore Hardness: 80

Polyamide Profile Color: Black

Standards: European Standard EN 14024:2004 & GB/T 23615.1-2017

Kronos Certification: IATF 16949:2016

Applications: Thermally Broken Aluminum Windows and Doors, Passive Windows, Energy Efficient Buildings, Passive House, Sustainable Buildings etc.

Kronos develops and produces various shapes of polyamide insulating profiles for different thermally broken aluminum windows and doors system.

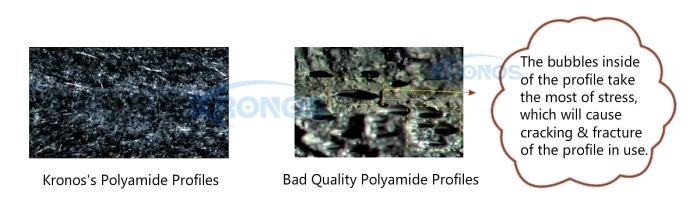

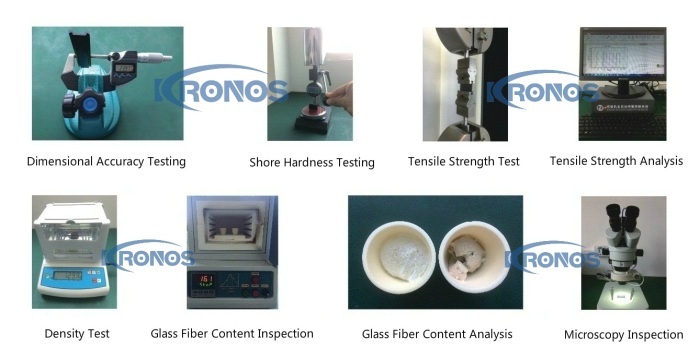

The Quality of Kronos's Thermal Struts-Glass Fiber Reinforced Thermal Insulating Polyamide Profiles is IMPECCABLE.

At Kronos Precision Polyamide Extrusion, all the Thermal Insulating Polyamide Profiles must be checked thoroughly prior to delivery.

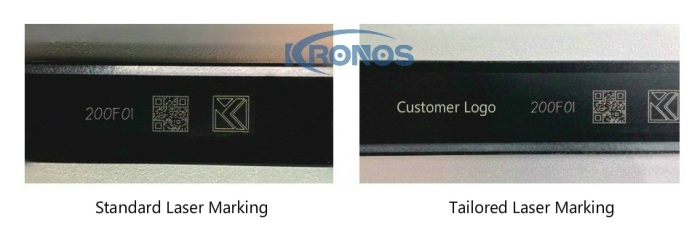

Kronos offers standard and tailored Laser Marking for easier traceability and improved quality control, adding extra value to your products and company.

The kronos Precision Extrusion team pays close attention to every single detail of the Thermal Insulating Polyamide Profiles.

Exchange of Know-How - The Milux Windows and the Kronos Precision Polyamide Extrusion Team

Whatever your thermoplastics extrusion challenges are, the friendly and professional specialists of Kronos Precision Extrusion are here for YOU.